Machine Vision

We specialize in the machine vision – optical methods of measuring and processing images from digital cameras. We supplement manufacturing machines and lines with the possibility of the camera control, especially focusing on checking the correct assembly of the product, checking the presence, measuring dimensions, reading barcodes and text. We provide a comprehensive solution of the task from the feasibility evaluation, delivery of the camera system, its integration into the production process, including the assembly, to the integration into the superior control system. Often, the task of machine vision is associated with the mechanical action intervention into the production – e.g. withdrawal of the nonconforming product from the conveyor belt and the like. For most of these cases, we can offer a solution. We use camera systems by the companies Keyence, Cognex, Moravian Instruments, Sick and Omron.

We offer:

- evaluating the feasibility of the inspection task

- design and delivery of the camera system

- installation at the customer

- integration into the superior PLC control system

- design and delivery of the action intervention in the production process

Control of the product completeness

Errors may occur during the automated assembly of the product. Some part of the product is omitted from the assembly or it is mounted incorrectly – oppositely oriented, positioned in the wrong place and the like. Many of these errors can be detected and the wrong product separated during the assembly.

Contactless size measurement

The contactless measurement often remains as the only way to measure something. When the measured shape is very small, located at a place that the measuring pliers cannot reach or the object is in the motion.

Reading of 1D and 2D codes, texts (OCR)

The station can be used for scanning of 1D (EAN 13, Code 128, …) or 2D (QR Code, Data Matrix, …) codes. Information from the read code can be the basis for further manufacturing operation. Reading of records, verifying the presence of the correct type of the product, and others.

Sorting of products

Sometimes, more product types are processed simultaneously. The products may differ from each other by colour, shape or other characteristics. If there is a requirement of sorting – to place products with the same characteristics to various locations – the solution may be the control station.

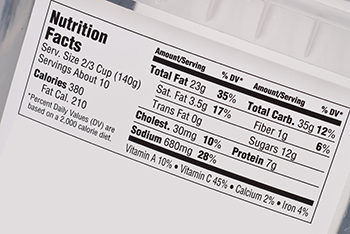

Control of the print quality

During the print of the packaging or the product there is a possibility of an error. A common cause is the absence of ink in the printer or the mutual displacement of the object and the print head. Except the ability to verify the presence of the printing, the station can read the text itself, and thereby control the accuracy of the printed series.

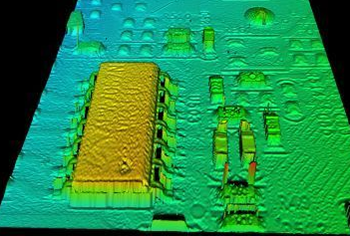

3D measurement

With the arrival of 3D cameras it became possible to control the scanned object more comprehensively. The 3D measurement results in a virtual 3D object that corresponds with the scanned pattern. On such object it is possible to evaluate the properties of the areas of interest, which is very difficult to obtain by other means. The dimensions of the protrusions, curvature, and others. We have experience with 3D LMI Technologies Gocator from Turck.